Soldering Accessories

Soldering Iron Tips

Try

to use the right size tip whenever you can. Smaller wires and circuit

boards require small fine tips, and mic cable onto an XLR would need

a larger tip. You can get pointed tips, or flat tipped ones (sometimes

called 'spade tips'). If you have a solder station with a desolderer,

you will also want a range of desoldering tips and cleaners.

Try

to use the right size tip whenever you can. Smaller wires and circuit

boards require small fine tips, and mic cable onto an XLR would need

a larger tip. You can get pointed tips, or flat tipped ones (sometimes

called 'spade tips'). If you have a solder station with a desolderer,

you will also want a range of desoldering tips and cleaners.

Soldering Iron Stands

These

are handy to use if you are doing several or more joints. It is a

heat resistant cradle for your iron to sit in, so you don't have to

lie it down on the bench while it is hot. It really is essential if

you are planning to do a lot of bench soldering as it is only a matter

of time before you burn something (probably your elbow resting on

the hot tip) if you don't use one.

These

are handy to use if you are doing several or more joints. It is a

heat resistant cradle for your iron to sit in, so you don't have to

lie it down on the bench while it is hot. It really is essential if

you are planning to do a lot of bench soldering as it is only a matter

of time before you burn something (probably your elbow resting on

the hot tip) if you don't use one.

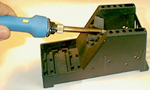

Clamps

I

strongly recommend clamps of some sort. Trying to hold your soldering

iron, the solder, and the wire is tricky enough, but when you have

to hold the connector as well it is almost impossible. The are however,

adjustable clamps that can be manipulated to hold both the connector

and the wire in place so you still have two free hands to apply the

heat and the solder. These are cheap items, and I know mine have paid

for themselves many times over.

I

strongly recommend clamps of some sort. Trying to hold your soldering

iron, the solder, and the wire is tricky enough, but when you have

to hold the connector as well it is almost impossible. The are however,

adjustable clamps that can be manipulated to hold both the connector

and the wire in place so you still have two free hands to apply the

heat and the solder. These are cheap items, and I know mine have paid

for themselves many times over.

Magnifying glass

If

you are doing work on PCBs (printed circuit boards) you may need to

get a magnifying glass. This will help you see the tracks on the PCB,

and unless you have exceptional sight, small chip resistors are pretty

difficult to solder on well without a magnifying glass. Once again,

they are not expensive, and some clamps come with one that can mount

on the clamp stand.

If

you are doing work on PCBs (printed circuit boards) you may need to

get a magnifying glass. This will help you see the tracks on the PCB,

and unless you have exceptional sight, small chip resistors are pretty

difficult to solder on well without a magnifying glass. Once again,

they are not expensive, and some clamps come with one that can mount

on the clamp stand.

Solder Wick

Solder

wick is a mesh the you lie on a joint and heat. When it heats up it

also melts the solder which is drawn out of the joint. It is usually

used for cleaning up solder from tracks on a circuit board, but you

will need a solder sucker to clean out the holes in the circuit board.

Place the wick on the solder you want to remove then put your soldering

iron on top of the wick. The wick will heat up, then the solder will

melt and flow away from the joint and into wick.

Solder

wick is a mesh the you lie on a joint and heat. When it heats up it

also melts the solder which is drawn out of the joint. It is usually

used for cleaning up solder from tracks on a circuit board, but you

will need a solder sucker to clean out the holes in the circuit board.

Place the wick on the solder you want to remove then put your soldering

iron on top of the wick. The wick will heat up, then the solder will

melt and flow away from the joint and into wick.

Solder Suckers

If

you don't have a solder station with desolderer, and you work on PCB's,

you are going to need one of these before too long. They are spring

loaded and suck the melted solder out of the joint. They are a bit

tricky to use, as you have to melt the solder with your iron, then

quickly position the solder sucker over the melted solder and release

the spring to suck up the solder. I find solder wick to be easier

to use and more effective.

If

you don't have a solder station with desolderer, and you work on PCB's,

you are going to need one of these before too long. They are spring

loaded and suck the melted solder out of the joint. They are a bit

tricky to use, as you have to melt the solder with your iron, then

quickly position the solder sucker over the melted solder and release

the spring to suck up the solder. I find solder wick to be easier

to use and more effective.

Fume Extractors

Solder

fumes are poisonous. A fume extractor will suck the fumes (smoke)

into itself and filter it. An absolute must for your health if you

are setting up a soldering bench.

Solder

fumes are poisonous. A fume extractor will suck the fumes (smoke)

into itself and filter it. An absolute must for your health if you

are setting up a soldering bench.

Next Page: Preparation